Features

Peroxide Free Machine

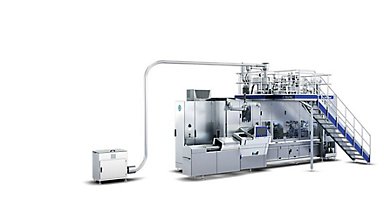

Tetra Pak® E3/CompactFlex

Tetra Pak® E3/CompactFlex Pasteurised Version

This version of Tetra Pak® E3/CompactFlex is for chilled products and does not require packaging material sterilisation. Hydrogen peroxide will only be required to sterilise the machine in a very small quantity.

Tetra Pak® E3/CompactFlex XH Version

This version of Tetra Pak® E3/CompactFlex is for Extended Shelf Life products and utilises one eBeam lamp to disinfect the inner part of the packaging material. Hydrogen peroxide will only be required to sterilise the machine in a very small quantity.

Mini Single Head Sealing

More homogeneous sealing quality

The transversal sealing of the packages is done by ultrasonic technology enabled by Mini Single Head Compact Transducer. It is a new component using single head instead of a twin head. This assures a more homogeneous sealing quality and enables machine capacity increase to 9'000 packs/hour.

New Operator Interface

Wide screen

The operator panel will have a new look and feel and a wider screen – in 16:9. More intuitive icons are available with added functionality and improved usability. The time required to perform the different operations has been reduced.

Two Optional Cleaning systems

Choose from full automatic or eco friendly cleaning

The customer will have the possibility to select between two external cleaning options with a chance to customise his own cleaning cycle! The two available pre-defined options are:

- A full automatic procedure ensuring a higher cleaning efficiency covering also the hygienic chamber.

- A more eco friendly option with a lower water consumption

The cleaning parameters are visualised at the operator panel and will be enabled for customisation so that the customer can tailor make it to better fit specific needs.

Web Position Active Control

Enhanced sealing quality and reduced dust

This new feature improves two important aspects of the filling machine functionality:

- Sealing quality because the web position accuracy is improved through a dynamic correction of the position

- Reduced dust because the device is not in contact with the edges of the packaging material

Breakthrough eBeam technology

The Tetra Pak® E3 platform is a series of filling machines that use eBeam technology to sterilise packaging material replacing the traditional hydrogen peroxide sterilisation process for packaging material while guaranteeing the same sterilisation performance. The eBeam sterilisation technology works by focusing a controlled beam of electrons on the surface of a packaging material to kill micro-organisms as it runs through the filling machine.

View video and find out more

Breakthrough eBeam technology

The Tetra Pak® E3 platform is a series of filling machines that use eBeam technology to sterilise packaging material replacing the traditional hydrogen peroxide sterilisation process for packaging material while guaranteeing the same sterilisation performance. The eBeam sterilisation technology works by focusing a controlled beam of electrons on the surface of a packaging material to kill micro-organisms as it runs through the filling machine.

View video and find out more

Benefits of eBeam technology

eBeam

Reduce operational cost

Breakthrough technology

eBeam

Improve environmental performance

Production flexibility

Electron beam technology for carton packaging material sterilization