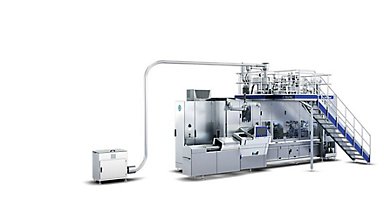

In the competitive world of chilled dairy production, the decision to invest in an end-to-end supplier is rarely taken lightly. For peace of mind, and maximum return on investment, producers need to know they’re making a choice that will optimise every part of their operation – from productivity and food safety to operator wellbeing. That’s why our Tetra Rex® filling systems are purpose-built to overcome your biggest operational challenges in dairy production, and come backed by our decades of food and beverage production expertise.

When it comes to productivity, even small inefficiencies can add up to substantial losses over time. One of the key issues when filling is a lack of precision – either overfilling, which results in product giveaway, or underfilling, which can lead to rejected packages and product waste.

Our Tetra Rex filling machines solve this with a proprietary algorithm and highly advanced control system that enables industry-leading accuracy. “We’re specifying plus-minus one gram on a 1,000ml package – that’s best in class and significantly better than our competitors, who average around plus-minus three grams,” says Christoffer Persson, Product Manager Tetra Rex Platform. And this precision doesn’t just reduce waste – it translates into direct financial savings at scale.

This degree of accuracy is one of the biggest advantages of our filling machines – and one not all producers are aware of. A machine launched earlier this year in Japan introduced the latest update to this optimised filling system, reinforcing our continued commitment to pushing performance boundaries.

Importantly, the Tetra Rex filling machines also eliminate splash-back during the ultra-fast 0.3-second fill cycle, reducing the risk of contamination in sealing areas and further improving line efficiency.

Food safety is non-negotiable in dairy production. Poor hygiene control during filling can lead to contamination, reduced shelf life, and, ultimately, reputational damage.

In chilled dairy, the weakest link defines the shelf life of your product, and the filling process plays a critical role. “The most common issue we see is a breach in the cold chain. But from the machine side, contamination or air leakage can also compromise food safety,” says Persson.

Tetra Rex filling machines tackle this in three main ways:

- Sterilisation with peroxide and UV light: Packaging material and closures are decontaminated in a controlled process. Uniquely, Tetra Rex filling machines use a dedicated peroxide spray specifically for closures, offering more thorough closure sterilisation compared to relying solely on the cap being disinfected together with the package.

- Overpressure environment: The filling environment is kept under constant positive pressure to prevent airborne contaminants from entering the system.

- Optimised, splash-free filling: Precise, rapid filling reduces the risk of milk splashing into sealing areas, which could otherwise lead to package integrity issues.

This carefully orchestrated system ensures that chilled dairy products leave the factory with the best possible chance of reaching consumers in optimal condition.

Operator safety is often overlooked in filling equipment discussions, but Tetra Rex filling machines put it front and centre. One key area is peroxide handling. As a hazardous substance, improper peroxide management can pose risks to human health.

“Our newest Tetra Rex filling machines include an internal emissions system that neutralises peroxide vapour via a built-in catalyser – so there’s no need to connect to external ventilation systems,” says Persson. “It effectively converts the peroxide into harmless air, ensuring levels stay well below EU legal limits around the machine.”

Another standout feature is the improved physical access and ergonomics. Instead of steep ladders, Tetra Rex filling machines now features wide staircases and platforms. This seemingly simple change can have a big impact. “If something happens to an operator on the upper platform, they can now be helped down safely. That wasn’t possible on older machines or on many competitors’ systems,” notes Persson.

For added protection, Tetra Rex filing machines also now come with advanced safety switch systems that prevent operators from bypassing safety interlocks. Unlike earlier models, these paired switches can’t be tricked with metal keys or dummy parts. “You would physically have to remove the sensor and reattach it – which is extremely difficult to do without setting off alarms,” says Persson.

A newer development, not yet widespread, is a centralised chemical refill system for non-peroxide cleaning agents. This system removes the need for manual pouring of chemicals, reducing spill risk and operator exposure. It’s another example of how we are evolving our technology to match not just regulatory demands, but real-world working conditions on the production floor.

Efficiency you can count on

Tetra Rex filling machines embody our commitment to smarter, safer, and more sustainable dairy production. And by choosing them, you invest in so much more than just machinery – you invest in peace of mind. Our Tetra Rex filling systems maximise your uptime, ensure product integrity, and protect your teams, giving you the reliability, efficiency, and support needed to thrive in today’s dairy market and safeguard your brand.