Dairies today face growing pressure to improve yield, while simultaneously boosting product quality and optimising the efficiency of their processes. To some degree, processing technologies have evolved to help them meet these demands. But when it comes to capacity especially, one piece of equipment has become a limiting factor in the processing line: the separator.

The traditional solution to this challenge has been to design processing lines with multiple separators. However, this approach has a number of clear drawbacks: from ballooning capital expenditures and higher demands on limited plant space, to an increase in energy and water consumption that multiplies both operating costs and the environmental footprint. As a result, there is greater need than ever before to support higher capacity needs within a single separator.

What limits separation capacity?

Multiple factors determine the maximum possible capacity of a given separator, but a key aspect is the total available separation surface area inside the bowl. To understand this better, it is helpful to consider the very first dairy separators manufactured in the 1880s. In these basic machines, a spinning bowl generated centrifugal force that separated cream and skimmed milk. The separation surface, however, was limited to the area of the bowl itself, meaning it was only possible to produce small batches at a time.

The change came with the advent of the disc stack a decade later. Each conical metal disc adds additional surface area for separation within the bowl. More discs mean more separation area. As a result, disc stacks enabled higher capacities that would ultimately bring about the transition to continuous dairy processing. It is for these reasons that disc stack technology remains the heart of dairy separation well over a century later.

The disc stack is the key to separation surface area within the bowl. More discs = more separation area.

Historically, increasing the size of a disc stack has of course meant increasing the size of the separator itself, but there is a limit to just how big a single piece of equipment can become. In addition to the space challenges of a bigger footprint, larger and heavier machines are more costly to produce and install. It takes more power to run them at the same speed as smaller models, with more water and chemicals needed to clean them. We are therefore right back where we started, facing similar challenges as when designing a line with additional separators.

Asking the right questions

To meet growing capacity and product quality demands, the challenge is therefore to increase the total amount of separation surface area, but not increase the size of the separator itself. In effect, we need to make the inside of the separator bigger than the outside of the separator. At first glance, this seems like a physical impossibility.

Or is it? At Tetra Pak, we have approached this problem in a different way, asking instead: “how can we add more discs into a disc stack without altering the footprint of the equipment or significantly changing the size of the separator bowl?” To answer this question, there are two key factors to consider. The most important is the amount of space required between each disc in the stack, and a secondary consideration is the shape of the separator bowl.

To meet growing capacity and product quality demands, we need to essentially make the inside of the separator bigger than the outside.

Disc spacing

For a smooth and efficient dairy separation process, it is vital to ensure equidistant spacing between each disc in the disc stack. Traditionally, this is done by welding metal spacers onto the discs. These spacers have been a reliable and effective way of providing uniform distance intervals between the discs, and the basic design principle has remained unchanged for over a century.

Spacing is thus key to the separator’s operation, but it also creates a capacity challenge. The greater the space between each disc, the fewer discs you can fit into the stack, reducing the potential separation surface area. Although there have been small improvements to address this over time, the welding method inherently limits the possibilities to increase the number of discs.

The solution is to remove the welded spacers entirely. By instead using a one-piece design with spacers micro-embossed directly into the disc, it is possible to minimise the space between each disc while keeping the distance uniform. This, combined with the potential to manufacture thinner discs, means additional space for discs without the need for larger equipment.

Disc spacing is key to the separator’s operation, but it also creates a capacity challenge. The greater the space, the fewer discs you can fit into the stack.

Bowl design

The shape of the separator bowl is yet another design element that has seen little change over the decades. Conventionally, the hood of the bowl is manufactured with a 15° angle. While a seemingly minor detail, this angle can reduce the available space inside the bowl and, as a result, further limit the number of discs you can fit into the stack. By modifying the hood with a 13° angle instead, it is possible to create additional room for increased separation surface area – without significantly altering the overall size of the equipment.

Modifying the hood of the bowl makes it possible to create additional room for increased surface area – without altering the equipment footprint.

In applications with high product-quality demands, such as milk powder production, increasing the number of discs enables significant improvements in skimming efficiency at maintained capacities. You can also better adjust the speed of the separator according to performance and capacity needs, running at reduced speeds to minimise energy consumption and thereby lower utility costs per litre of product sold.

In other words, capacity is about more than just capacity. Additional separation area gives you greater flexibility to have an optimal configuration according to your specific processing demands. Produce more than previously while keeping the same level of separation performance – or improve efficiency while running at current capacities. This means you can more easily produce multiple products on a single processing line, adjusting the separator as needed to match the required processing characteristics.

Additional separation area gives you greater flexibility to have an optimal configuration according to your specific processing demands.

Unlocking the full potential of your separation technology

Being able to fully take advantage of that flexibility, however, comes down to much more than just the available separation area. Here, you need to consider the design of the entire machine.

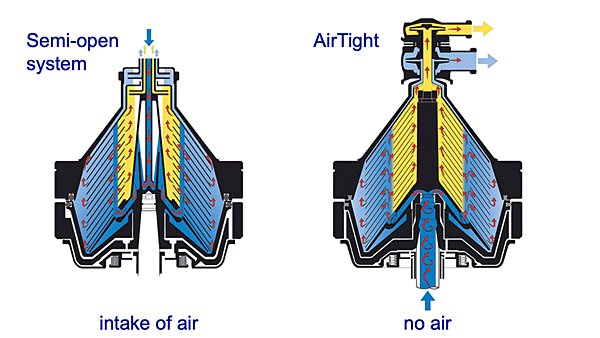

The key is having a fully closed separator design with hermetic seals that prevent air intake during processing. Hermetic separation technology makes it possible to easily adjust the speed of the equipment according to your needs without running the risk of, for example, overflow. With semi-open machines, on the other hand, making these adjustments would require time-consuming manual alterations that involve disconnecting the piping and opening up the machine.

To learn more about how hermetic separation allows you to unlock the full potential of your equipment explore the two articles below.