UHT treatment for food and beverages

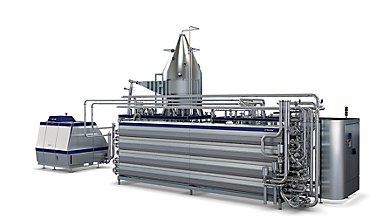

UHT, or Ultra High Temperature treatment requires both a sterilizer and an aseptic unit (for packaging the product). It is used for low acid (above pH 4.6) products such as UHT milk, UHT flavoured milk, UHT creams, soya milk and other dairy alternatives. The same process is also used to sterilize prepared food, such as soups, sauces, desserts, tomato and fruit preparations, and baby food.

In UHT treatment, the goal is to maximise the destruction of microorganisms while minimising the chemical changes in the product. That means finding the optimal combination of temperature and processing time for different types of food. Tetra Pak offers two alternative methods of UHT treatment: direct or indirect.