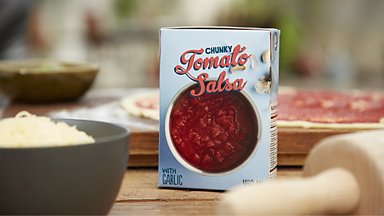

Tomato preparations

While tomato preparations as a category is growing, so are the demands placed on producers – from consumers wanting food innovation and better value to the need to handle wide quality variations in raw tomato pastes. Our tomato processing solutions help you standardise raw tomato paste, which enables cost-effective, flexible procurement and ensures production efficiency and consistent quality worldwide. And when it comes to food packaging, we have the innovative and sustainable packaging solutions to pack a range of tomato products.

See more about tomato manufacturing, our Tetra Pak tomato processing and packaging below.