Benefits

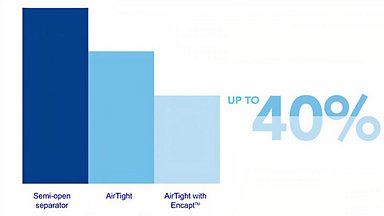

The combination of AirTight with our patented Encapt™ technology enables superior performance and end-product quality combined with a broad operational flexibility – while using up to 40% less energy than other separators.1

By using low pressure and reduced air friction around the separator bowl, Encapt™ cuts the energy consumption of a Tetra Pak® Separator with AirTight technology by 7-9 kW. This reduces both your operational costs and your resource consumption.

Encapt™ technology is available as an option for:

Tetra Pak® Separator H60, H75, D70, BB45, BB55, BM40, BM50, C40, C50, W50, W60, T45, A16 and WD50.

AirTight technology

Click on the film to see how it works.

AirTight technology

Click on the film to see how it works.

Low pressure = less friction

Low pressure = less friction

Encapt™ technology

Encapt™ technology

Rethinking resources

Food and beverage producers face growing challenges in energy, water, and waste management. Addressing them requires a combination of technology and food expertise, tailored to your operations. Our comprehensive portfolio of products and services, backed by decades of experience in food applications, can help you reduce your energy, water, and waste while simultaneously delivering cost benefits.

1 Production scenario: 20 hours of run time/day; 340 production days/year; hot milk skimming at 55 000 l/h with including feed and booster pumps.