Benefits

Powerful efficiency

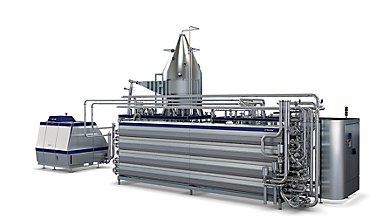

Tetra Pak® Indirect UHT unit is a processing unit for highly efficient, continuous ultra-high temperature treatment of dairy products. The unit is of aseptic design, and a tubular or plate heat exchanger is used for indirect heating to obtain a product that can be stored at ambient temperatures.

Quick facts

Continuous UHT heat treatment for liquid food products under aseptic conditions

Capacity

1,000 – 40,000 l/h

Applications

Tetra Pak Indirect UHT unit is suitable for dairy products such as milk, flavoured milk, cream, yoghurt drinks, buffalo milk and formulated dairy products, as well as for other low acid products such as soy milk. Combinations with non-dairy applications such as juice, tea and coffee are also possible.

Features

Product-to-product regeneration

Reduced steam and cooling medium need

Direct product-to-product regeneration enables low steam consumption (only 20 kg/1000 kg of product) and makes 92% heat recovery possible. Additional energy is saved by achieving an outlet temperature that is ~15 °C above the inlet temperature. This means a drastic reduction in the cooling medium required.

Fouling control

Longer running time to save money

Fouling is minimized so the equipment can run for up to 40 hours with good quality white milk, meaning a lower cost for every litre produced. This is achieved by optimizing the set-up with a temperature-controlled, protein denaturation holding tube, accurately controlling both ΔT and pressure drop, and controlling the flow in the hot water circuits.

Bottom-filling balance tank

Lower product losses

The balance tank features a special bottom-filling design and a sharp border between mixing phases. It can save up to 75 litres of milk* at every product change (at 15,000 L/h), compared to the traditional filling of a flat-bottom balance tank. The inlet valve arrangement shortens the mixing phase, and a frequency-controlled pump further reduces energy consumption.

*Calculation is based on comparing Low loss balance tank and Tetra Therm Aseptic Flex headerbatch solution. Production scenario: 15,000 L/h capacity,3 product changes/day,300 production days/year

IntelliCIP™ 2.0

Cleaning adapted to need

Thanks to IntelliCIP™ 2.0, a new technology (patent pending WO2013092414), cleaning results can be monitored in-line with the help of CIP sensors. This means cleaning settings can be optimized depending on the degree of fouling, resulting in more uptime and a reduction in utilities consumption.

Automatic damper

For longer running times

Homogenizer dampers absorb pressure variation and shocks before and after the homogenizer. Automatic air refill maintains the air cushion in the homogenizer damper to ensure smooth operation. Without the air cushion, vibration and cavitation would occur and shorten the running time. Fully automated CIP is included - increasing operator safety, improving hygiene, and further optimizing the production cycle.

Hibernation

Spend less getting ready

If there is a time gap between pre-sterilisation and production, the unit can be set to automatically enter into hibernation mode. This optional function reduces the amount of energy and cooling water during sterile water circulation by up to 60% compared to traditional water circulation – without losing the aseptic status of the plant.

Heat exchanger protective panels

Great energy savings potential

Protective panels built around the Tetra Pak® Tubular Heat Exchanger encapsulate the equipment and contain the heat. This gives up to 6% savings on energy consumption compared to heat exchangers without panels. With added insulation, savings can increase to 11%. The panels also increase operator safety since they reduce the risk of contact with hot surfaces.

Heat exchanger floating protection system

Longer lifetime and exceptional efficiency

Aseptic product in the inner tubes of the Tetra Pak® Tubular Heat Exchanger flows at a higher pressure than the untreated product on the shell side. A floating protection system allows for thermal expansion, greatly reducing the risk of damage from cracking, and consequent loss of sterility. In addition to extending lifetime, this improves food safety.

Rethinking resources

Food and beverage producers face growing challenges in energy, water, and waste management. Addressing them requires a combination of technology and food expertise, tailored to your operations. Our comprehensive portfolio of products and services, backed by decades of experience in food applications, can help you reduce your energy, water, and waste while simultaneously delivering cost benefits.