Quick facts

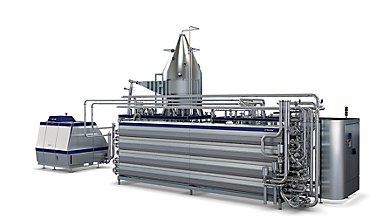

Continuous, gentle indirect UHT treatment unit with coiled heat exchanger for high viscous products, with or without particles

Capacity

2,000 - 15,000 l/h, depending on application

Applications

Desserts, fruit preparations with large particles, sauces and soups with large particles or other high viscous products with or without particles where high particle integrity is required.

Features

Tetra Pak® Coiled Heat Exchanger

Maintains integrity of particles

The heat exchanger is designed to handle particles gently. There are no moving parts, a short retention time due to efficient heat transfer and just a few inlet and outlet connections. All this enables very gentle mechanical treatment, which means that particles remain intact.

Heat transfer calculation model

Gives excellent product quality

Thanks to a very accurate way of calculating the heat required to process each individual product, heat loads are optimized in this unit. The system volumes remain small and retention times short. All this reduces the risk of overcooking and maintains the product's natural taste

Flow pattern in coiled tubes

Minimizes product losses

The coiled heat exchanger is designed in such a way as to achieve the ‘Dean effect’ - a natural law that comes into effect when particle turbulence is very high. A velocity of up to 4 metres per second in the tube makes for highly effective heat transfer. There is a relatively small volume of product in the coil at any given time, and therefore very little product is lost during emptying and filling.

Hygienic design

Assures food safety

All components are carefully selected for tough operating conditions. Cleaning programmes are designed to assure food safety and optimized production efficiency, and enable you to create unique settings for caustic/alkali, high/low temperature, concentration and circulation time. Advanced automation reduces the chance of human error and enables full traceability.

Flexible hardware configuration

Product versatility and future proofing

Carefully selected, tested and proven components make it easy to expand and upgrade your system to meet future capacity and production needs. There are also solutions for both your current and your future product portfolios, since the design enables you to process products – aseptic/non-aseptic or smooth/particulate – with a wide range of viscosities.