Diversify with us

Working with us, you’ll get over 40 years ofexpert advice along the way as you explore plant-based production. We can help you optimise atevery step, from selecting the best raw materials and ingredients to efficiently processing,packaging, and bringing your plant-based product to market successfully.

That’s our edge.

Convert your line to plant-based food production

The plant based category is growing, and innovation is essential. Diversify your plant-based offering with the right solutions, and a flexible approach.

With you at every step of your plant-based journey

Success in plant-based beverages depends on many factors: raw materials, suppliers, technology, product, marketing, and expertise. Discover how we can help at every step.

Integrated Plant Solutions for plant-based beverages

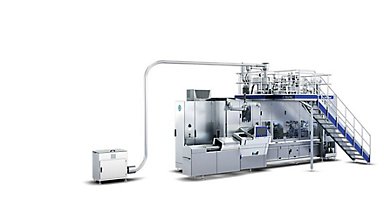

What you see is a line of steel equipment. What you get is decades of plant-based food processing and packaging expertise combined with sophisticated food industry automation and experience from maintaining and optimising thousands of plants all over the world – an unmatched integrated end-to-end solution for producing plant-based beverages. We can offer your desired quality to the lowest possible total cost of ownership.

Watch the video to learn more.

Integrated Plant Solutions for plant-based beverages

What you see is a line of steel equipment. What you get is decades of plant-based food processing and packaging expertise combined with sophisticated food industry automation and experience from maintaining and optimising thousands of plants all over the world – an unmatched integrated end-to-end solution for producing plant-based beverages. We can offer your desired quality to the lowest possible total cost of ownership.

Watch the video to learn more.

Equipment for plant-based beverages

In devising plant-based food processing solutions, we help you minimise energy and water consumption, and cut down on waste – all without compromising on product quality. Talk to us about reducing both impacts and costs, for example by deactivating oat enzymes at lower temperatures or switching from direct (steam injection) to indirect heat treatment.

Consumers want perfect products every time, and mixing is a key part of ensuring this. Our extensive line of equipment will help you master this critical step.

Buffer tanks balance processes by temporarily storing product on the line. Our tanks for aseptic and non-aseptic products boost efficiency and cut product loss.

Colours, flavours, vitamins and more benefit from aseptic dosing. Our dosing solutions meet any need – from same-ingredient dosing to injections before filling.

Whether you separate milk or remove particles from juice, you’ll get excellent product quality, efficiency and flexibility from our separation equipment.

Continuous in-line or manual batch, our blending solutions make sure your products feature consistent flavour, colour, texture and other key characteristics.

Our CIP equipment is known for its high accuracy. This means faster cleaning, greater uptime, lower utilities consumption, and less risk of food safety issues.

Perfecting homogenisation takes the right technology, optimally configured and operated. Discover our reliable, cost-effective and sustainable solutions.

Producing tea our soy? Our semi--continuous extraction system cools and clarifies your tea, while our soy unit extracts concentrate via sophisticated processes.

UHT treatment is about temperature and time. Our direct-treatment option gives you high product quality, while indirect treatment maximises cost-efficiency.

Pasteurisation makes products safe, extends shelf life, reduces spoilage and can even alter characteristics. Our low-TCO solutions will meet your every need.

What will they drink tomorrow?

Are you curious why consumers are choosing more and more plant-based, and which ingredients and functional claims will be top of mind? Well, we asked them. In this video you’ll learn what they said.

What will they drink tomorrow?

Are you curious why consumers are choosing more and more plant-based, and which ingredients and functional claims will be top of mind? Well, we asked them. In this video you’ll learn what they said.