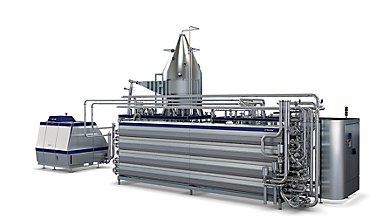

Oat processing equipment for oat-based drinks

A versatile favourite

Oat drinks have found their loyal crowd thanks to their versatility – numerous clean-label, flavoured, functional and blended products can be found on the store shelves today. With a flexible production line, you can cater to all preferences.

25% more oat beverage, zero fibre waste

Improve TCO for oat flour beverage lines

Sign up and read the article Thank you for signing up

Diversify with a flexible line

Sign up and read the article Thank you for signing up

Best-practice lines for oat beverages

Best-practice line for whole oat beverages

This line lets you produce oat beverages with high nutritional value, zero by-product waste and high production efficiency. This is achieved by using the whole oat grain in the final beverage. First, we reduce particle size with three-stage grinding and through homogenization. This is followed by a highly controlled enzyme treatment. Powerful high shear mixing and homogenization optimise beverage properties and heat treatment ensures food safety.

View this lineBest-practice line for oat beverages based on oat flakes or grains

This line includes grinding and a highly controlled enzyme treatment and deactivation process to achieve the desired product flavour. Fibre separation, powerful high shear mixing and homogenisation optimise beverage properties. Heat treatment ensures food safety.

Explore Best-practice lines for oatBest-practice line for oat beverages based on oat flour

This line combines high efficiency with low environmental impact. It lets you achieve desired product quality and reduce your consumption of energy, water and raw materials. The line begins with powerful high shear mixing. Next comes a highly controlled enzyme treatment and deactivation process. Fibre separation, powerful high shear mixing and homogenisation optimise beverage properties. Heat treatment ensures food safety.

Explore Best-practice lines for oatBest-practice line for oat beverages based on oat compound

This line begins with powerful high shear mixing to give you full formulation control, allowing you to fine tune products to match consumers’ texture and taste preferences. Choose between two different heat treatment methods to ensure food safety.

Explore Best-practice lines for oat

Get the latest to your inbox

Sign up for more information Thank you for signing up

Packaging for oat beverages

Expert support for product innovation

The content couldn’t be loaded. Please refresh the page or try again later.

Minimise costs with Integrated Plant Solutions for oat

Unlock the full value of a true end-to-end, pre-configured food and beverage production solution. Integrated and optimised from raw material reception to packages on pallet, pre-configured lines deliver reliable output backed by service solutions and performance guarantees. Each line combines three dimensions – equipment, automation, and digital solutions and services – to deliver a low and predictable total cost of ownership (TCO).

1 Conventional solution gives 8 litres of oat beverage from 1,1 kg of oat. The line for whole oat beverages gives 10 litres of beverage (with 10% oat in the beverage) from 1,1 kg of oat.