Benefits

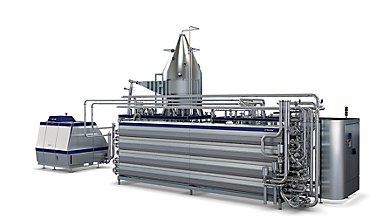

Innovation is what drives us, and it is what keeps our technology at the cutting edge. The Tetra Pak® Direct UHT unit is our latest step forward in aseptic technology that is designed to help you optimise production and meet the needs of an ever-changing market.

Direct UHT - for quality and flexibility

At Tetra Pak, we master both the major UHT technologies, so we can focus on what will give you the results you are looking for. If it’s premium product quality you’re after, then the Tetra Pak Direct UHT unit is the way to go. You get truly premium quality and ultra-flexibility to handle a wide portfolio of products in one unit.

State-of-the-art direct UHT technology

Direct UHT treatment puts minimal heat load on a food product thereby preserving the overall quality and nutritional value while reducing the impact on taste. Our state-of-the-art direct UHT technology is truly flexible with more than 100 options and a couple of combined heating solutions

Do you wish to treat many different liquid foods by UHT?

Tetra Pak Direct UHT unit gives you the flexibility to handle a wide portfolio in a single unit whether choosing direct mode or a combined heating solution.

Features

Steam injection

Preserve product quality

Direct steam injection gives you instant heating from 80°C (application dependent) to the UHT temperature, followed by temperature equilibrium and instant condensation, all thanks to the ring-nozzle steam injector. Heating and cooling of the product is practically instantaneous. That’s how our direct UHT technology creates commercial sterility while applying very little heat load to your products. This results in less chemical changes and therefore a final product more similar to the original unprocessed product. There are less colour and taste differences than with indirect UHT technology as well as less effect on nutritional values.

Steam infusion

Minimize shear forces

The Tetra Pak Direct UHT unit is available with either injection or infusion or both. When it comes to shear-sensitive products such as whipped cream containing stabilizers (e.g. starch or Carrageenan), steam infusion offers certain benefits. The basic principle of steam infusion is to heat a product by passing it through an atmosphere of steam. You will get the same high quality UHT product with infusion as with injection, but with less shear. This gives greater stability for shear-sensitive products. However, on the cost side, infusion gives you a 4-8% higher operating cost than injection because the process requires more steam and cooling water and results in slightly higher product losses.

Flash cooling

No need for costly ice water

The condenser is a separate unit. This allows it to operate at a higher temperature level (outlet water: up to 72°C compared to 65°C before). You do not have to use expensive ice water to fine-tune the temperature in the condenser cooling circuit, giving you lower energy costs. In addition, the separate condenser is easier to clean and service.

Combined heating solutions

Variety of temperature programmes

Instead of buying two different units, you can purchase a ready-made combi model offering either injection or infusion or both. You can also choose equipment to manage both direct and indirect heating methods. Choose the heating solution that suits your products best and adapt it easily if your needs change in future because flexibility is built in. There are three modes to choose from:

Direct UHT mode - For “added value” products and superior product quality.

Plus mode (combining direct and indirect heating) - For longer shelf life and optimized economy.

Indirect mode - Lowest operating cost and environmental impact. For longest possible shelf-life and long running time.

Automatic homogenizer damper

For longer running times

Homogenizer dampers absorb pressure variation and shocks before and after the homogenizer. Automatic air refill maintains the air cushion in the homogenizer damper to ensure smooth operation. Without the air cushion, vibration and cavitation would occur and shorten the running time. Fully automated CIP is included - increasing operator safety, improving hygiene and further optimizing the production cycle.

Floating protection system

Longer lifetime with less risk of damage

Aseptic product in the inner tubes of the Tetra Pak® Tubular Heat Exchanger flows at a higher pressure than the untreated product on the shell side. A floating protection system allows for thermal expansion of the tubes, greatly reducing the risk of damage from cracking, and consequent loss of sterility. In addition to improving food safety, this feature extends the lifetime of the heat exchanger.

Low-loss balance tank

Low product losses

Due to a very specific solution of the inlet valve arrangement of the balance tank, we have managed to reduce the mixing phase of the product. Other improvements apply to the inlet solution which carries an electronic level control. The frequency-controlled product pump is also linked to this device. In addition, a frequency-controlled pump will have a lower energy consumption.

Low water, CIP and waste consumption

Reduced utilities and product losses

Compared to Tetra Therm® Aseptic VTIS, Tetra Pak® Direct UHT provides up to 6% water savings due to its compact design, which reduces the demand for fresh water. Additionally, chemical savings can reach up to 37% thanks to the unique design of the steam injector, flash vessel, and condenser, allowing for the same cleaning efficiency with less detergent. Product loss is reduced by 48%, attributed to the compact design and the new low-loss balance tank, which enables a greater control of the mix-phase during both the filling and emptying phases.*

*Tetra Pak® Direct UHT unit compared to Tetra Therm® Aseptic VTIS , based on 23,000 l/h, 144 hours per week, and 50 weeks/year