Baby food

Baby food production is rapidly developing, especially around science-driven innovations for added value and care beyond simple nutrition. Our optimal baby food processing solutions unleash your product innovation and enable you to produce a wide range of baby foods – from ready-to-eat products to fruit purees and purees with particles.

Processing lines for baby food

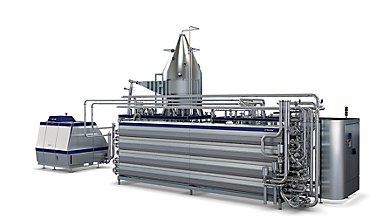

Best-practice continuous line for baby food

This line handles the production of smooth to small particulate purées. It allows you to produce a broad range of products – from smooth fruit purées to purées with spaghetti pieces – that are wholesome and have higher nutritional value and fresh taste and colour. The recipe-specific shear rate in mixing and optimized heat treatment achieves desired product characteristics with high production efficiency. Our line enables safe production with exceptional quality, efficiency and flexibility.

Explore Best-practice lines for baby foodBest-practice continuous particulate line for baby food

This line handles particles up to Ø25 mm with excellent particle integrity. It allows you to produce a greater variety of products – from smooth fruit purées to purées with beef and potatoes – that are wholesome and have higher nutritional value and fresh taste and colour. Gentle processing prevents the breakdown of particle shape and maintains even distribution. The recipe specific shear rate in mixing and temperature program achieves the desired product characteristics. Our line enables safe production solutions with exceptional versatility, quality and efficiency.

Explore Best-practice lines for baby foodBest-practice continuous ready-to-drink line for baby food

This line enables the production of liquid ready-to-drink infant formula. It meets demands for safe, convenient infant formula with higher nutritional value and fresh taste and colour. It ensures accurate and consistent raw ingredient dosing. And it minimizes heat load for maximized nutritional value with secure bacterial reduction. Our line enables uncompromised food safety, high quality and production efficiency.

Explore Best-practice lines for baby foodTetra Recart for baby food

The Tetra Recart portfolio is the smart choice for baby food production. Learn which sizes are available, and discover the potential benefits for baby food producers.