Benefits

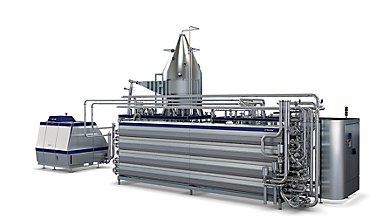

Tetra Pak® Indirect UHT unit is a processing unit offering smarter and smoother operation for ultra-high temperature treatment of dairy products. The unit is of aseptic design, and a tubular heat exchanger is used for indirect heating to obtain a product that can be stored at ambient temperatures.

Quick facts

Continuous UHT heat treatment for liquid food products under aseptic conditions

Capacity

1,000 – 40,000 l/h

Applications

Tetra Pak Indirect UHT unit DC is suitable for dairy products such as milk, flavoured milk, cream, yoghurt drinks, buffalo milk and formulated dairy products, as well as other low acid products such as soy milk. Combinations with non-dairy applications such as juice, tea and coffee are also possible.

Features

Direct steam in the final heater

Smart base for longer runs at lower costs

The streamlined Tetra Pak® Indirect UHT unit uses direct steam in the shell side of the final heater, which enables production run times of up to 8 hours. The steam pressure is accurately controlled to prevent product burning. For run times of up to 16 hours, an optimized set-up with a temperature-controlled, protein-denaturation holding tube and hot water circuit option is available.

Product-to-product regeneration

Optimized steam consumption

Low-loss balance tank

Minimizes product loss

A smart balance tank configuration makes it possible to remove the maximum amount of water before product enters the tank, thus reducing the mix of water and product. This method lowers the number of litres in the mix phase by over 50%, leading to a significant reduction in product losses.

Closed pre-sterilization loop

Better value with reduced energy consumption

During pre-sterilization, hot water is circulated in the module. By directing the hot water over the pressurized side as a closed loop, you eliminate the need for cooling in the return line. This shortens start-up time and reduces utility consumption.

Heat exchanger protective panels

Great energy savings potential

Protective panels built around the Tetra Pak® Tubular Heat Exchanger encapsulate the equipment and contain the heat. This gives up to 6% savings on energy consumption compared to heat exchangers without panels. With added insulation, savings can increase to 11%. The panels also increase operator safety since they reduce the risk of contact with hot surfaces.

Heat exchanger floating protection system

Longer lifetime and exceptional efficiency

Aseptic product in the inner tubes of the Tetra Pak® Tubular Heat Exchanger flows at a higher pressure than the untreated product on the shell side. A floating protection system allows for thermal expansion, greatly reducing the risk of damage from cracking, and consequent loss of sterility. In addition to extending lifetime, this improves food safety.